In today's fast-paced manufacturing industry, efficient and accurate data management is crucial for ensuring product quality, improving operational efficiency, and meeting regulatory requirements. The barcode traceability system has emerged as a powerful tool for achieving these goals in production lines.

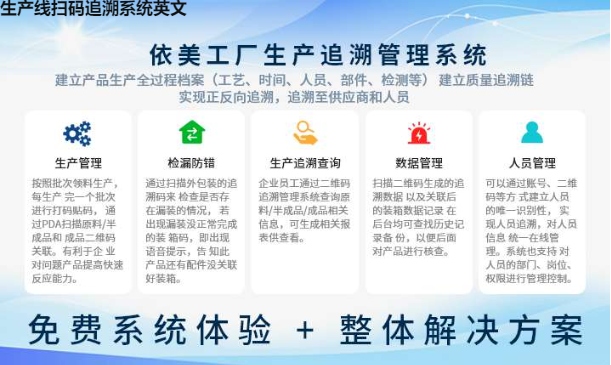

The barcode traceability system enables the tracking and tracing of products throughout the entire production process, from raw materials to finished goods. By utilizing barcode technology, each unit of material or product is assigned a unique barcode, allowing for easy identification and data capture. This comprehensive data collection and management system provides real-time visibility into key production factors such as personnel, processes, equipment, and materials, enabling businesses to enhance operational efficiency and quality control.

One of the primary benefits of the barcode traceability system is its ability to streamline data management and eliminate manual errors. By automating data capture through barcode scanning, the system ensures accurate and reliable information input. This eliminates the need for manual data entry, reducing the risk of human error and improving data accuracy. With better data management, businesses can make informed decisions, improve production planning, and optimize resource allocation.

Furthermore, the barcode traceability system provides real-time production insights and performance metrics. By capturing data from each production process, such as labor input, machine performance, and material consumption, businesses can analyze and monitor key performance indicators (KPIs) in real-time. This helps identify bottlenecks, optimize production processes, and improve overall efficiency. By being able to quantify and evaluate production performance, businesses can set benchmarks and implement continuous improvement strategies.

Quality control is another critical aspect that the barcode traceability system addresses. By tracking each unit of material or product, businesses can easily identify and isolate any defective or non-conforming items. This allows for prompt corrective actions, reducing quality issues and customer complaints. Moreover, the system facilitates the implementation of quality control measures, such as standard operating procedures (SOPs) and quality checks at various production stages. This ensures that products meet the required quality standards before shipment or distribution.

The barcode traceability system also offers comprehensive reporting capabilities. By analyzing the collected data, businesses can generate detailed production reports, including production yields, efficiency rates, and quality statistics. These reports provide valuable insights into production performance, allowing businesses to identify areas for improvement, optimize processes, and make informed decisions.

The application of the barcode traceability system is extensive and can benefit various industries, including manufacturing, food and beverages, pharmaceuticals, and automotive. From ensuring the authenticity and traceability of raw materials to product recalls and warranty tracking, the system caters to different industry needs. Ultimately, the barcode traceability system provides businesses with a reliable and efficient solution for data management, process optimization, and quality control, leading to improved operational efficiency and customer satisfaction.

In conclusion, the barcode traceability system for production lines offers an effective solution for data management, efficiency, and quality control. By utilizing barcode technology, businesses can streamline operations, enhance visibility, and make data-driven decisions. With its comprehensive reporting capabilities and industry-wide applicability, the barcode traceability system is a valuable tool in today's manufacturing industry.